|

The World of Crafts |

|

|

| Home page ---> Glass ---> Glass Bead Making in Odumase Krobo |

|

The World of Crafts |

|

|

| Home page ---> Glass ---> Glass Bead Making in Odumase Krobo |

Glass Bead Making in Odumase Krobo, Ghana

| Locally-made beads are sold at the Odumase Krobo bead market on Saturday and Wednesday. | |

|

|

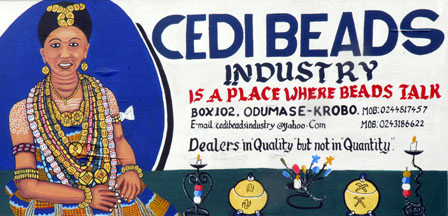

| Cedi Beads Industry sell their beads both locally and internationally all week. For a tour, to buy beads, to arrange a class, or for more information, please contact Cedi at P. O. Box 102, Odumase-Krobo, Eastern Region, Ghana, West Africa, telephone +(233) 0244-817457, cedibeadsindustry@yahoo.com |

|

| Nomoda (Cedi) Djaba and his family and employees enjoy demonstrating the bead making process to the many visitors who find their way there. They produce five types of glass beads: opaque and transparent beads from recycled powdered or chipped glass, painted beads, and they melt and reform antique chipped and broken beads. | |||

|

|

|

|

| Transparent and opaque beads are made from colorful recycled glass bottles. | A steel mortar is used to crush some of the glass into a fine powder. | Kudjo Owusu showed how terracotta clay was modeled into a cylinder, then cut with a machete and shaped by hand. He stamped the clay with a wooden tool to produce multiple depressions of the same size and shape. The mold will be fired to 800o to 1000o C in the bead kiln before being used for bead making. | |

|

|

|

| Nomoda Mark made this specially shaped reusable clay mold to produce the monkey bead shown. | Cedi demonstrated how the molds were filled with powdered glass that had been sieved. Ceramic mason stains were added to some of the powders make stronger colors. | |

|

|

|

|

| The red leaf stem of the cassava plant is used to form the hole in beads made from powdered glass. The powdered glass is added in colorful layers to produce patterned beads. | |||

|

|

|

| The wood-burning kiln was constructed from termite mound clay. The molds in the kiln are resting on automotive leaf springs that are supported by recycled car axles. | ||

|

|

|

| The filled molds are heated for 20 to 35 minutes at 600o to 800o C until the glass powder melts, then they are removed from the kiln to cool for around an hour. The cassava stem keeps the glass at bay before charring, forming a perfect hole. | ||

|

|

|

| Some glass is chipped instead of crushed. Window glass is wiped clean, then broken with a rock. A wood frame on the stone mortar helps keep the chips together. | ||

|

|

|

|

| Molds are reused many times. Before filling them with glass, they are dipped in a mixture of kaolin and water to keep the molten glass from sticking. | Fingers are used to fill the molds with chipped glass that is then heated until molten. | ||

|

Links: Ashanti Glass Bead Making in Daabaa, Ghana Ashanti Adinkra in Ntonso, Ghana Ashanti Kente Weaving in Bonwire, Ghana Ashanti Kente Weaving in Adawomase, Ghana Ewe Kente Cloth Weaving in Denu, Ghana Lost Wax Casting in Krofofrom, Ghana Ga Coffins in Teshie, Ghana Carol Ventura's Home Page |

| Photographs and text by Carol Ventura. |